How Does Precision Impact Structural Steelwork Fabrication?

Why Accuracy Is Crucial in Steel Cutting and Shaping

Accuracy ensures components meet strict dimensional, geometric, and surface finish requirements critical for functionality and safety. Precision measurement and CNC machining enable adherence to specifications like material thickness and flatness, according to the norms of construction. Improper cuts or unleveled steel plates can create defects in downstream processes like welding or mold making, impacting product quality.

Accuracy ensures components meet strict dimensional, geometric, and surface finish requirements critical for functionality and safety. Precision measurement and CNC machining enable adherence to specifications like material thickness and flatness, according to the norms of construction. Improper cuts or unleveled steel plates can create defects in downstream processes like welding or mold making, impacting product quality.

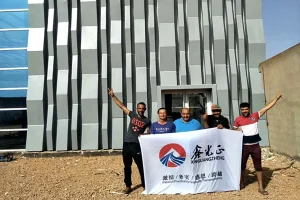

Precision is crucial to guarantee a fit for each steel component within the entire framework’s design integrity. Take the Drug Warehouse in Algeria by XINGUANGZHENG as an example—utilizing Q355Band Q235 B steel materials with surfaces ensured accurate sizing and flawless appearances were achieved. This specific method not only minimizes the risk of errors on site and conserves materials but also keeps safety levels on the completed structure.

The Importance of Precision Welding in Structural Stability

Welding is a field where accuracy is highly critical since it has a direct impact on the strength and longevity of joints within a steel structure of buildings.

In the case of constructing the Aviation Design Institute in China as an illustration situation when distinct testing platforms were created for aero engine parts and precision welding played a role therein. This endeavor called for not only robust structural integrity but also durability in elevated conditions. The thorough focus on welding specifics guaranteed the fulfillment of these criteria in a span of 33 days.

Why Is Stability Essential in Structural Steelwork?

The Role of Fabrication Accuracy in Load-Bearing Strength

In the Garment Factory in Ethiopia which covers an area of 100,000 meters and houses various workshops and office buildings as an example, precise manufacturing was crucial to ensure that every part could bear its intended weight effectively. This detailed method helps in averting issues and prolongs the longevity of the structures.

How Precise Connections Enhance Overall Durability

When it comes to steel fabrication the strength of the connections plays a crucial role in determining durability levels making it an important factor to consider.

During endeavors such as the Paint shop in Thailand, featuring overhead cranes within storage spaces accurate links played a crucial role in sustaining operational effectiveness during intense utilization scenarios. These links didn’t just offer steadiness. Also paved the way for potential expansion if required.

In addition to durability considerations in construction projects, like the Shandong Gold site near the sea that necessitates high corrosion resistance measures for longevity and structural integrity, specialized coatings are carefully applied to address this issue with meticulous attention to detail. This thorough approach guarantees that the structures can withstand challenging conditions effectively.

Why Choose XINGUANGZHENG for Your Structural Steelwork Fabrication?

Key Features of XINGUANGZHENG’s Structural Steelwork Products

High-Quality Materials Used by XINGUANGZHENG

XINGUANGZHENG opts for premium-grade steel variants, like Q355b and Q235b renowned for their strength and long-lasting durability. These chosen materials undergo rigorous selection processes to guarantee compliance with the demanding specifications of diverse projects ranging from warehouses and factories to aviation research facilities.

Advanced Machinery and Technology

XINGUANGZHENG relies on cutting-edge machinery and technology to ensure accuracy and efficiency in their operations. The company runs six production plants with seven steel structure production lines two purlin production lines and two plate production lines. These modern facilities allow them to manage projects with exceptional precision.

How XINGUANGZHENG Ensures Precision in Every Stage of Fabrication

Detailed Quality Control Measures Adopted by XINGUANGZHENG

The dedication of the company to accuracy shines through in its quality assurance procedures. They have a team of than 100 experienced technical experts who supervise each step of the manufacturing process. Starting from choosing materials to putting the final product they adhere to stringent guidelines to guarantee that every part meets global benchmarks.

When dealing with endeavors such as the creation of an aviation design institute in China that involved crafting special test platforms for aero engine parts, ensuring quality control was crucially important. The whole setup was put in place in 33 days owing to good planning and flawless execution. This level of precision not only adds to the structural strength but also diminishes the possibility of errors in the construction process.

XINGUANGZHENG’s devotion to testing processes and mastery of managing humongous projects best describe the unwavering passion for making infrastructure safe and secure around the globe. If you have any questions about structural steelwork fabrication, do not hesitate to contact us!

Frequently Asked Questions about Structural Steelwork Fabrication

Q: What is fabricated steelwork?

A: Steel fabrication is crucial in the construction of stunning buildings that emphasize both utility and beauty. Steel fabrication is the process of transforming raw steel into accurate components, which are used to construct buildings as well as other buildings.

Q: What is the process of structural steel fabrication?

A: Steel fabrication is the art of producing different products, mostly steel, through bending, cutting and welding raw materials. Fabricators apply different methods to transform raw materials into end products for construction, manufacturing and others.

Q: What is the difference between steel fabrication and metal fabrication?

A: Steel fabrication would probably include welding, cutting and bending—simple processes because of steel’s homogeneous nature. Metal fabrication may entail more specialized processes to account for various metals’ reactions to heat or pressure.

Q: How is technological innovation shaping the future of structural steelwork fabrication?

A: Digitalisation, automation, and smart manufacturing are transforming the structural steel production process. These have increased accuracy, productivity and scalability of factories to meet increasing demand for quality steel for infrastructure and prefab buildings as required by national policy.

Q: What are the challenges to structural steel fabricators staying profitable?

A: Unstable raw material prices (i.e., coke and iron) and intense industry competition are the key problems. Fabricators get around these by refining cost control, instituting energy-efficient technologies, and going after high-value applications like industrial complexes and skyscrapers, where the accuracy and durability of steel maintain demand independent of market fluctuations.